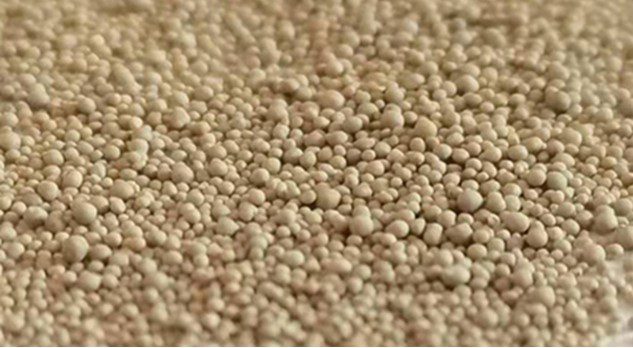

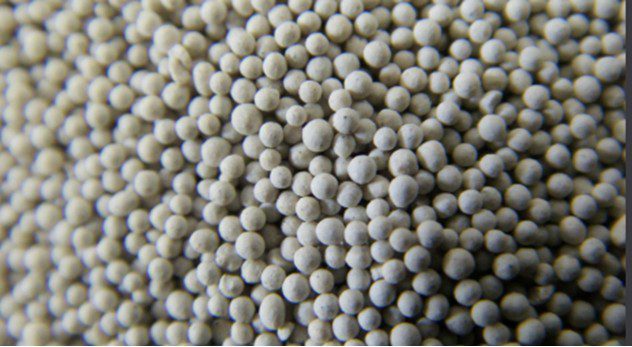

High-Quality Ceramic Foundry Sand

Welcome to Hawthorn Industries, a leader in ceramic foundry sand distribution for North and South America for the past 20 years. Our foundry sand is derived from high-quality calcined bauxite, having high aluminum oxide contents, and is manufactured into nearly perfect spherical shapes, which can be screened to the exact American Foundry Society (AFS) fineness range you need.

The Benefits of Working With Us

If your foundry’s customers require precision metal castings, order your ceramic foundry sand from Hawthorn Industries. We offer a high-quality product at an affordable price. We offer a high-quality product at an affordable price. Some of the benefits of using our ceramic foundry sand include:

- Reduced health hazard

- Range of particle sizes

- Low thermal expansion

- Single-sand system

- High reclamation yield

Ceramic sand is a proven substitute for other sands such as chromite, silica, and zircon and can be used in a wide range of foundry processes.

If you’re interested in trying ceramic sand for your foundry, place an order with Hawthorn Industries today. We have a U.S.-based warehouse so we can send our orders out within hours once we receive them.

Call us for foundry sand samples and product references. With our industry experience, we know the products we work with and we know what works well. Consult with us about which ceramic foundry sand would be the best fit for your applications. We provide our foundry sand on a works basis trial, meaning if the product works, then you pay for it.

To learn more, call us at (414) 916-4348. You can also get in touch via the contact form at the bottom of this page.